Secondary Glazing and Costed Alternatives – detailed 2023 Case Study

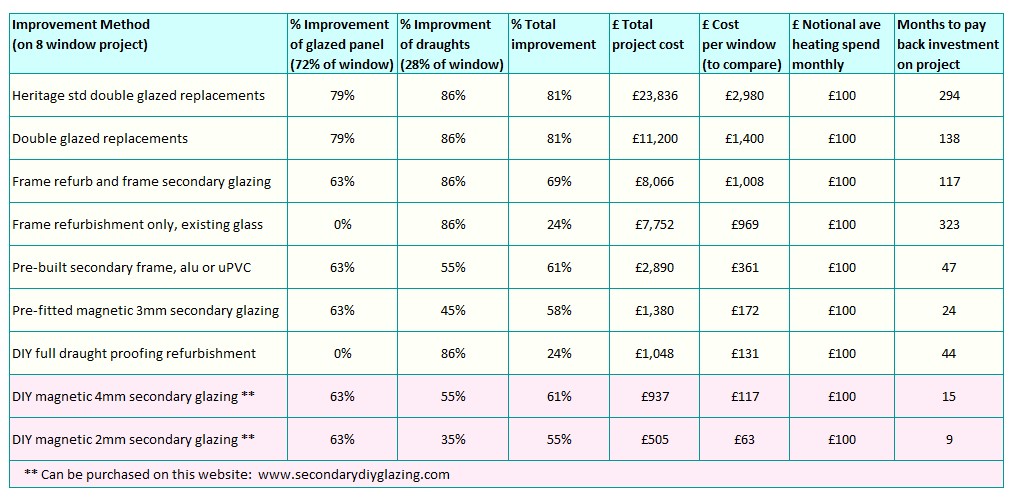

Windows are usually the biggest source of heat loss in a room, especially single glazed windows. There are a lot of different ways to improve their thermal performance, ranging from complete replacement to simple secondary glazing, but it can be difficult working out which to choose. How effective are they all? How much is the initial outlay? How long will it take for this sum to payback in savings on the heating bill? This study answers these questions for the alternative window insulation methods described.

Secondarydiyglazing.com first looked at this in 2013, as an objective cost comparison, from a customer’s point of view. Since then of course there have been Covid lockdowns, with many more people working from home, and more recently the energy crisis, resulting in huge jumps in heating bills, plus energy saving awareness is much higher; these have pushed many more households into wanting or needing to improve window insulation.

This updated study is more detailed than just comparing costs, as it uses the efficiency findings of two Historic Scotland test projects to calculate payback. These independent measures are covered in more detail on our Heat Retention page but are summarised below.

Window Insulation Efficiency – Key Findings

The independent studies found that:

- On a typical single glazed sash window, heat loss was 72% through the glass and 28% around the frame

- In laboratory testing, replacement double glazed glass panels generated a 79% heat saving and secondary glazing a 63% saving on the 72% glass heat loss

- Refurbishment of draught proofing around the frame improved heat retention by 86% on the 28% frame heat loss

By combining glass and draught improvements we reached an overall insulation improvement. However, as secondary glazing does not reduce the draughts but by covering the whole window cavity it blocks them, this improves insulation but will not be as effective as reducing the draughts themselves, so we have made an assumption based on secondary sheet thickness that frame insulation will be 55% for 4mm sheet, 45% and 35% for 3mm and 2mm sheet as thinner sheet will be more affected by the cold air behind them still coming through the frame edges.

- The Total Project Costs include all work described, delivery and Vat, but might be subject to extras like Surveys (by the installing company)

- Cost per window is likely to be lower for 8 windows than a quote for 1 or 2

- Heating Spend will vary considerably between households and time of year. The notional figure is needed to provide a comparison. If your bill is greater than this, your saving will payback your investment quicker (and if less, slower)

- As above, the Months to Payback figure is best used for comparative purposes rather than as a definitive period.

The property in the study is a Victorian flat with attractive but fairly standard sash windows. This is a good example, as the windows are draughty, a little mis-shapen and with light damage to a few of the catches, making them hard to close fully – typical sashes, in fact, and in need of improvement as they make the flat cold and expensive to heat in cold weather. For the purposes of the study we have decided that the owner of the flat wants to keep the character of the windows, but look in detail at all options for insulating them.

The window details:

- All 8 windows are “one over one” vertical boxed sash windows with 3mm glass single glazed frames, on the first floor, fronted by a small private car park

- Room 1 (Sitting Room) has 2 windows 1600mm x 915mm, and 2 windows 1600mm x 690mm

- Room 2 (Bedroom) has 2 windows each 1600mm x 740mm , and 2 windows 1600mm x 690mm

- Although draughty, the frames, sills and boxing are in adequate condition and with no obvious serious defects

The descriptions below elaborate on those described in the table, being in roughly descending cost for the full 8 window project. There is no provision for painting / staining wooden fittings or employing an independent tradesperson to do the work:

- Full replacement of existing boxes, frames, sills (if required) and fittings, including removal of old windows and installation of new. The finished windows would be double glazed and in keeping with the original “heritage” style, using good quality timber. The services offered included fitting anytime of the year, on a one-out, one-in basis, i.e. not requiring temporary glazing or sheeting during the work. About 2 days work to fit, using one person outside and one inside, with scaffolding. The “Rolls Royce” solution!

- Frame replacement, with new double glazed units, and replacement beads, cords and fittings. Refurbishment of boxing and sills not included, as the new frames are dropped into existing window surrounds and structure. Some modern features included in the price, such as the ability to remove frames for painting without needing to remove sash cords and weights.

- Refurbishment and trimming of existing frames, with replacement of cords, beads and fittings, and including a magnetic secondary glazed panel on each frame. This looked a neat and effective system, being installed by the supplier, but is essentially magnetic secondary glazing (see 9 below) plus draught-proofing (see 7 below) at what we thought was rather a high price. Whether work would take place on or off site was not specified.

- Refurbishment of existing frames, with replacement of cords, beads and fittings. Includes draught proofing of refitted single-glazed windows, but not repainting. The work would be done off-site, requiring temporary glazing or weatherproof sheeting in the 2-3 week refurbishment period, although one room at a time is possible. Not suitable for autumn or winter. The unsurveyed quote is likely to allow for the current state of the frames being poor and the amount of work that might therefore be required on them.

- Vertical DIY sliding secondary glazing, covering the window cavity, in either PVC or aluminium. All systems include glazing but do not address the outer windows other than to cover them. The systems all allow the windows to be locked open or closed, and to be glazed in plastic sheet or glass. They are not counterweighted and the complexity of fitting was not established. Products of this type may require the window surrounds to be perfectly flat.

- Magnetic secondary glazing cut and stuck onto pre-cut plastic glazing sheets, delivered ready for DIY installation. A very easy system to fit, with no extra cost for the supply of jointed panels, although the joint is a little basic. Essentially, product 8/9 but with some of the strip-sticking and measuring done in advance, but surprisingly only using 3mm PETg sheet on all window sizes.

- DIY draught proofing kits only, with no Secondary Glazing added. Replacement beads, cords and brushes, unpainted, requiring frames to be removed and “a sound knowledge of woodworking” plus, we assume, good woodworking tools, so not quite DIY for many householders. Some companies will arrange for a competent person to fit these kits, for an appropriate charge.

- DIY secondary glazing products supplied by secondarydiyglazing.com, using 4mm cut-to-size solid Polycarbonate sheet with Magnetglaze Extreme 25mm edgings. Self-install with full written instructions and video, with performance improved using better draught proofing on outer windows.

- Similar secondarydiyglazing.com products, but this time 2mm Polycarbonate sheet and 12.7mm Magnetglaze. Also self-install with instructions and video, would also benefit from extra outer window draught proofing.

The products above should contain something to suit every expectation and pocket, with the simplest secondary glazing being 47 times cheaper than the most expensive, but still delivering very good insulation and paying back relatively quickly. We recommend thinking through what you want and shopping around as it is easy to make an online commitment to buying these products, but it can be harder to get full details of exactly what the product and service includes, which is necessary; for example, what is the lead time from order to delivery or fitting, and what parts are included and will you be required to fit any of them? If necessary, contact a supplier with your technical questions as they should be able to answer them (unless they are just re-selling someone else’s product).

For DIY products, they can still look very smart, they are usually “non-invasive” i.e. can be removed without damaging the existing windows, making them suitable for most listed or conservation area projects. They will save you money and energy so will also add value to your property (as will all the measures above, even if you never recoup the outlay). Remember that your time is required for fitting DIY systems, and it is well worth taking your time.

If we are to concentrate on one main piece of advice for DIY / online products it would be to double check your measurements carefully as you will be responsible for any mistakes, and for supplier installed products, check thoroughly what the price does and doesn’t include.

Author’s note – prices correct as at February 2023, but treat this Case Study as a guide only! Tubeway (Sales) Ltd (who operate secondarydiyglazing.com) believe all products surveyed to be suitable for use and all companies to be reputable.